Afra Protein

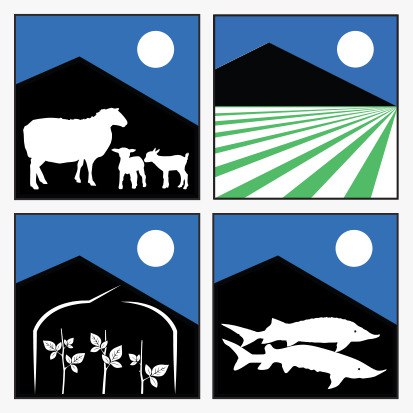

Afra Protein, as one of the subsidiaries of Afra Holding, operates in four sectors: livestock breeding, poultry, aquatics, and production of their feed.

Livestock Breeding: In this sector, the companies of the Sarv Group, as the largest industrial sheep breeding complex in the country, are active in breeding imported Roman and Lacaune breeds with the aim of producing milk, red meat, and breeding livestock.

Poultry Breeding: In this field, the production group Urum Chekavak, Royan Exim, Afra Makian, and Fadak companies are engaged in producing about 30 million one-day-old broiler chicks, 26,500 tons of chicken meat, and 7,000 tons of table eggs annually.

Aquatics: In the aquatics sector, Niksa Development Plan Company, as the largest fish cage farming complex, operates with a production capacity of 3,000 tons of sea bass annually.

Production of Various Feed for Livestock, Poultry, and Aquatics: In this sector, the feed production factory Nasim Sahar Pak Mehr Khalij Fars, poultry feed factories and full fat factories of Aryan Protein, as well as three factories belonging to the Urum Chekavak chain, are active.

Part of Afra Protein’s products is used as input materials and supplies in the subsidiaries, and another part is marketed and sold to partner companies and the consumer market.

Afra Protein at a Glance:

+3000

tons of

Fish Produced Annually

+7000

tons of

Eggs Produced Annually

+26,500

tons of

Poultry Meat Produced Annually

+30

Million

One-day-old Chicks Produced Annually

+120

tons of

Sheep Milk Produced Annually

+156

tons of

Red Meat Produced Annually

Afra Protein Services

Production of Various Feed for Livestock, Poultry, and Aquatics

In the subsidiaries of Afra Oil, after oil extraction from oilseeds, the resulting meal is used either as flakes or pellets in the subsidiaries of Afra Protein for producing various feeds for livestock, poultry, and aquatics, and part of it is also sold to partner companies.

By using the resulting meals, required grains, vitamins, and other necessary compounds, various types of livestock, poultry, and aquatic feeds are produced and offered to the market either in bulk or packaged forms. This process is carried out based on different feed rations ordered by customers or consuming subsidiaries, utilizing the latest global technologies, under various standards, and with strict quality control.

In this important process, subsidiaries such as Nasim Sahar and Aryan Protein play significant roles.

Breeding of Various Light Livestock

Afra Protein, a protein subsidiary of Afra’s Integrated Food Value Chains Holding, in addition to supplying, producing, and selling light meat and dairy livestock in covered units, is also responsible for slaughtering and packaging light and heavy livestock through the Incheh Borun slaughterhouse.

Among the subsidiaries of Afra Protein are Sarv Zera’, Sarv Dam, and Incheh Borun companies, which create value in this integrated chain.

Breeding of Various Broiler Chickens and Laying Hens and Pullets

The main activities of Afra Protein group include production of livestock, poultry, and aquatic feed, breeding of various broiler chickens, and laying hens and pullets.

Part of Afra Protein’s production, including one-day-old chicks and laying pullets, is consumed as input materials in subsidiaries of Afra Holding, and the rest is sold to partner companies and the consumer market.

Subsidiaries under Afra Protein include Royan Exim, Afra Makian, Fadak, and Urum Chekavak companies.

Breeding and Production of Various Aquatic Species

Breeding various aquatic species in covered units such as Niksa Development Plan Company is another activity of Afra Protein in the protein products sector. Its products are consumed domestically in the country, and part of them is also exportable, especially to Gulf countries.

Niksa Company, as the first and largest fish cage farming and production company in the country with an annual capacity of 3,000 tons of fish, has a significant role in this segment of Afra’s integrated value chain and plays an important role in increasing fish meat production in the country.

The subsidiary companies of Afra Protein

Urom Chavak Production Group

The fully integrated Urom Chavak chicken and poultry meat production chain, with more than 40 years of experience in producing day-old broiler chicks and chicken meat, is one of the most prominent and reputable production chains in the west of the country. The group began its cooperation with Afra Protein in 2023.

Read more

Urom Chavak Poultry Production Group began operations in 1985 with the establishment of broiler units. By 2013, it had completed the production chain and obtained a license with a capacity of 20,000 tons per year. Today, “the complete zero-to-hundred Urom Chavak chicken meat production chain” boasts nearly 40 years of effective and efficient activity, recognized as the exemplary provincial production chain in 2020, the national health-oriented industry model unit in 2021, the top national entrepreneur in 2022, among other honors. It operates for the poultry industry and the people of West Azerbaijan Province through its integrated chain, which includes livestock and poultry feed plants, breeder farms, hatcheries, broiler farms, slaughterhouses, and distribution centers.

Overview of Urom Chavak units:

Grandparent poultry unit (1 unit): Established in 2016, the Urom Chavak grandparent poultry unit operates with four production lines and a total capacity of 37,800 birds.

Hatchery unit (1 unit): Zarrin Par Hatchery, a wholly owned unit, has a capacity of 11 million fertile eggs annually. With the installation of new equipment in phase two, its capacity will reach 22 million fertile eggs per year.

Feed factories (three plants for livestock, poultry, and aquaculture feed): Urom Chavak has three active factories producing feed for livestock, poultry, and aquatic species.

Poultry slaughterhouse: The Urom Chavak poultry slaughterhouse operates at a capacity of 6,000 birds per hour, making it one of the busiest slaughterhouses in western Iran, with a monthly output of 1,500 tons of chicken meat.

Poultry farms: The group owns or manages approximately 60 broiler farms (owned, leased, and contracted) and 12 breeder farms across various cities of West Azerbaijan Province.

- Owned poultry farms: Producing 300,000 birds per cycle, located in Uroma and Naqadeh.

- Leased poultry farms: Producing 250,000 birds per cycle, located in Uroma and Naqadeh.

- Contract/partnership poultry farms: About 41 partnership farms across West Azerbaijan Province, with a capacity of approximately 1.3 million birds per cycle. These farms operate under partnership, fee-based, and exchange contracts.

Urum Beh Fam Veterinary Clinic:

Urom Chavak operates an independent veterinary unit that supplies the group with necessary veterinary inputs, including medicines, vaccines, and biological materials.

Chain stores:

- Over 320 Urom Chavak product retail outlets across West Azerbaijan Province (147 in Uroma and 45 in Naqadeh)

- More than 150 branch locations of chain stores

Other capabilities of Urom Chavak Production Group:

- Direct employment for 760 people and indirect employment for over 2,000 people

- Stable and guaranteed supply of poultry for the northwest of the country

- Production of poultry in grades A and B

- Supply of poultry for households in the province and exports to target countries

- Contribution to the country’s strategic reserves through slaughtering for the Livestock Support Company

- Supply of poultry to provincial organizations, offices, institutions, and agencies at all times

Titles and honors:

- National top cooperative (2015–2017)

- Selected provincial exporter (2017)

- Provincial exemplary entrepreneur (2018)

- Provincial top exporter (2018)

- Provincial top exporter (2019)

- National production champion (2019)

- Provincial top production chain (2020)

- National health-oriented industry model unit (2021)

- National top entrepreneur (2022)

Afra Makian Iranian Company:

Afra Makian Iranian Company currently operates two independent units for layer hen breeding and pullet rearing, named Afra Makian Iranian and Fadak, located in the provinces of Qazvin and Markazi.

Read more

Afra Makian Iranian Unit:

The Afra Makian Iranian unit is situated on a 23-hectare site in the Yansabad area of Qazvin, along the old Tehran–Qazvin road. It includes two separate operations: pullet rearing and layer hen breeding.

Pullet Rearing Unit (Layer): This unit operates with four rearing halls, with a capacity of 60,000 birds per three-month cycle.

- Two Layer Hen Units: This operation includes 11 production halls, with a total capacity of 372,000 birds, producing approximately 2,000 cartons of eggs daily. In order to increase production capacity, the establishment license for the layer hen unit has been obtained for 1,345,000 birds. Construction of the new halls will begin shortly.

Fadak Unit:

The Fadak unit is located in Markazi Province, Zarandieh County, in the village of Qaleh Mohammad Ali Khan, covering an area of approximately 50 hectares. It consists of two separate operations for pullet rearing and layer hen breeding.

- Pullet Rearing Unit (Layer): This unit has a capacity of 260,000 birds, raised in cages, built on a 3-hectare plot. It is equipped with modern poultry farming technology, providing optimal rearing conditions thanks to up-to-date equipment and the cage-rearing system.

- Layer Hen Unit: Following the renovation of existing halls and the addition of three new halls, the layer hen capacity of this unit has reached 300,000 birds, with the ability to produce 1,600 cartons of eggs daily during peak production.

Royan Exim Company:

Royan Exim Company is located on a 14-hectare site in Malard County, Tehran Province, and operates in the rearing of broiler pullets with a capacity of 410,000 birds.

Read more

This facility has recently been renovated and upgraded with modern equipment, giving it the capacity to produce a significant share of the country’s chicken meat—amounting to 1,000 tons per cycle—which represents about 20% of Tehran Province’s broiler meat production capacity.

Sarv Group

Sarv Group operates through its companies Sarv Dam Novin Qazvin, Sarv Rud Novin Qazvin, and Incheh Borun Agro-Industry Complex in livestock breeding (imported Lacen and Roman breeds from France) and laying poultry. Besides these, the group owns two active companies named Sarv Zera Novin Qazvin and Sarv Gol Novin Qazvin, engaged in horticulture, agriculture, and greenhouse activities.

Sarv Dam Novin Qazvin

Sarv Dam Novin Qazvin Company operates on an area of 464 hectares, utilizing the latest technology in the livestock industry to produce animal products. The first phase of this complex was established with a capacity of 15,000 breeding animals and currently has about 14,000 animals as the company’s assets. Construction of the next phases is underway to reach a capacity of 20,000 breeding animals by the end of 1404 (2025-2026).

Read more

Currently, the livestock complex, benefiting from approximately 10,000 square meters of covered space, is industrially breeding Roman and Lacen sheep breeds in a closed area.

Milking Unit:

The milking unit covers an area of 1,500 square meters, equipped with modern and advanced milking machines with a daily milking capacity of 10,000 sheep heads. At present, it can produce 10 tons of raw milk daily and aims to produce 20 tons per day by the end of 1404.

Poultry Farming:

This unit, covering about 18 hectares, is under construction with equipment installation ongoing. The poultry project includes laying hens and pullets with a capacity of two million laying hens in four farms and one million pullets in two separate farms.

Import of Fresh and Frozen Meat:

The complex has started importing fresh and frozen red meat from Australia, India, Brazil, Kazakhstan, Mongolia, and Russia with the required licenses. Imported meats comply with the highest international quality standards and have health certifications from the Veterinary Organization of Iran and are distributed to sales centers.

Sarv Zar Novin Qazvin

This company owns the country’s largest industrial sheep breeding unit, with a capacity of 14,000 breeding heads (ultimate target: 20,000) of Roman and Lacaune breeds (imported from France), producing approximately 10 tons of milk daily.

Read more

Intelligence (BI) and modern management systems in breeding are among the company’s key initiatives. Besides livestock production, Sarv Zar Novin Qazvin is also active in forage production.

Sarv Rud Novin Qazvin

Sarv Rud Novin Qazvin will be established on 10 hectares. Currently, it has obtained the necessary permits for sturgeon fish farming, and the facilities are in the design phase.

Incheh Borun Agro-Industry Complex

Incheh Borun Cooperative Company was established in 1390 (2011) with the goal of building the first industrial light and heavy livestock farm in Golestan Province with a capacity of 1,500 heads of light livestock and 100 heads of heavy livestock per shift.

Read more

Operations began the same year after obtaining the necessary permits from the Jihad Agriculture Organization and the Veterinary Office of Golestan Province. Located on about 32 hectares at the Incheh Borun border area, since Afra Protein’s participation, the company has used the latest industrial livestock technology, the most modern machinery, and world-class equipment to update its slaughterhouse. The slaughterhouse includes three pre-cooling chambers, a processing tunnel, zero-degree cold storage, upper and lower packaging lines, industrial wastewater and human waste treatment, incinerator furnace, and production of blood powder. The company implements other development plans, including converting waste to code-al, producing meat powder from inedible waste, and producing bone powder. In addition to the slaughterhouse, Incheh Borun Complex has an 8,000 square meter livestock farm capable of breeding and holding over 5,000 heads of light livestock and also owns 16 hectares of pomegranate orchards.

Niksa Development Planing Company

Niksa Development Plan Company, located in the Persian Gulf, was established in 1393 (2014) with the mission to produce high-quality seafood based on a commitment to developing a healthy food culture. Within one year, it successfully launched its marine farm located 14 kilometers from Kish Island and 4 kilometers from the coastal point of the Niksa Fisheries Town, spanning over 60 hectares with an annual production capacity of 3,000 tons of sea bass.

Read more

This complex includes 24 marine fish cages, a command barge (with storage capacity of 330 tons of feed and an automated feeding system), support vessels, and a dedicated pier. By applying unique knowledge and technology in the fish production chain at Niksa, full and precise monitoring of product health and quality from production to final consumption is ensured to deliver products meeting global standards. At Niksa, every detail at every stage is under strict control.

The main goal of the hatchery is to provide fish larvae (eggs) as a key production input. In the nursery, juvenile fingerlings are cared for before being transferred to the sea. The purpose of this section’s operation is to produce fingerling fish ready for stocking in the marine farm equipped with 24 fish production cages. The nursery section was put into operation in December 2019. With the completion of the nursery complex and the creation of a production capacity of 30 tons of fish per cycle, Niksa added another key link to its production cycle.

Arian Protein

The Arian Protein Fars complex includes a corn processing factory (flour and grits production), a high-fat feed (full-fat soybean) factory, and a poultry feed production plant. In addition to supplying part of the country’s demand, with the establishment of grain and edible oil storage facilities, it will soon have the capability to export to neighboring countries.

This production unit is located on a 30,000 square meter land in Amirabad Port, Mazandaran Province, and consists of the following components:

Read more

- Animal and Poultry Feed Factory: Under construction with an annual production capacity of about 72,000 tons of pellet and crumble feed, equipped with the most advanced and unique facilities to produce products complying with international standards. This unit, having warehouses and silos with a storage capacity of 30,000 tons of raw materials, is considered one of the highest quality feed production units in the country.

- Plant Protein Factory (Full-Fat Soybean):

With an annual production capacity of 30,000 tons of full-fat soybean and 20,000 tons of corn grits and flour, which began operation in the first half of 1403 (2024). Full-fat soybean is a rich source of protein and fat widely used in animal and poultry nutrition. This product is obtained by processing soybean seeds and, due to its valuable nutritional compounds, plays an important role in improving production performance and the health of livestock and poultry. Soon, a concentrate and supplement production line with a capacity of 10 tons per hour will be established in this unit.

Use of the latest technologies and devices in the production of ready-made poultry feed and plant protein (full-fat soybean), proper production line design, employment of the latest and smartest automation software using Siemens (Germany) and Schneider (France) technology, continuous monitoring and control of the production process, strict adherence to quality control principles from raw materials to final products, and the presence of a fully equipped laboratory for food and microbiological analysis are all prominent features of the Arian Protein complex.

The poultry feed and full-fat soybean factory is responsible for producing ready-made feed in pellet, crumble, and full-fat soybean forms for livestock, breeder hens, and broiler farms. According to the holding’s general policy, production is based on scientific and practical principles, continuous progress, and improving product quality. To this end, the feed production unit maintains continuous information exchange and interaction with poultry nutrition specialists, university professors inside and outside the country, and knowledge-based companies to keep pace with modern science and achieve the holding’s high goals.

- Edible Crude Oil Storage Site: Located on a 10,000 square meter land with 10 storage tanks, currently operating with a storage capacity of 20,000 tons.

Employment: Currently, 30 people are employed in this complex, and after full operation, it will create employment for more than 80 people.

Nasim Sahar Khalij Fars

Nasim Sahar Pak Mehr Khalij Fars complex, located in Imam Khomeini port, has been established on a 41,000 square meter land with the most advanced and modern equipment and facilities, with an annual nominal capacity of 72,000 tons of livestock feed, 72,000 tons of poultry feed, and 100,000 tons of aquaculture feed. This unit, with warehouses and silos for storing raw materials with a capacity of 20,000 tons, is considered one of the highest quality and best-equipped feed production units in the country.

Read more

The use of the latest technologies and machinery in feed production, proper design of the production line, use of the latest and smartest automation software with Siemens (Germany) and Schneider (France) technology, continuous control and monitoring of the production process, strict adherence to quality control principles from raw materials to final product, and the presence of a fully equipped laboratory for food and microbial analysis are all prominent features of this factory. This factory is responsible for producing ready-made feed in pellet, crumble, and extruded forms for livestock farms, breeder hens, broiler chicken farms, and fish and shrimp farming.

According to Afra Holding’s overall policy, production is based on scientific and practical principles, continuous progress, and improving product quality are the priorities of this unit. In this regard, the feed production unit maintains continuous exchange of information and interaction with nutrition specialists and professors from reputable universities inside and outside the country, as well as knowledge-based companies, to keep pace with modern science and advance the high goals of Afra Holding.

This company, with firm faith in the role of knowledge and research in developing its industry, has allocated part of its resources — financial, infrastructural, and human — to the research and development department to foster innovation and continuous improvement within Afra Holding. It strives, through scientific research and studies, effective communications with national and international scientific-research institutions, and the expertise and advice of its specialists and consultants, to provide the best assurance to face all new challenges and opportunities and to sustainably feed future generations.

Employment: Currently, 70 people are employed in this unit, and after full operation, close to 200 people will be working.